SUMMARY AND KEY FINDINGS

Soylent was born out of the desire to use science and technology to offer sustainable and nutrient-dense products that could be accessible to everyone. After 6 years of striving to deliver on our founding sustainability principles, we decided to put ourselves to the test and we commissioned an independent Life Cycle Analysis (LCA) on our Soylent bottled drinks to find out how we stack up and help us set our sustainability goals for the future. Here are some of the key findings:

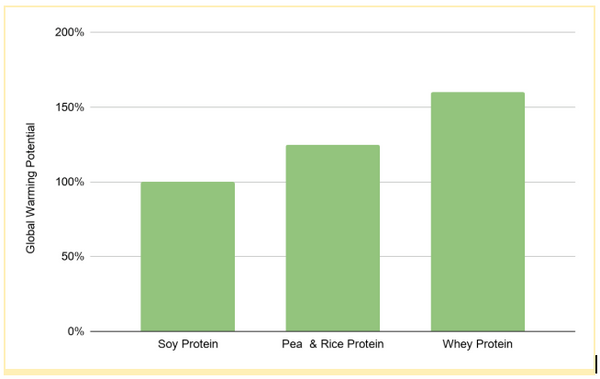

- The LCA showed us that soy protein isolate continues to be the most sustainable solution on all measures to deliver nutritious complete protein in Soylent drinks. Soy protein contributes 50% less CO2 than whey protein and 25% less than a pea/rice protein combination in our application.

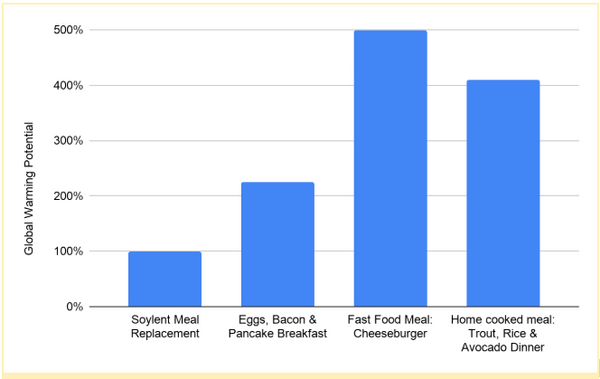

- Despite the environmental cost of our packaging, the LCA results showed us that Soylent bottled meal replacements are significantly more sustainable on most measures of sustainability than the fast food meal and home-made meals analysed in this study. Compared to Soylent, a traditional American breakfast contributes 2 times more CO2 emissions while a fast food cheeseburger contributes 5 times more CO2 emissions.

- Like all aseptic bottle manufacturers, it came as little surprise to us that Soylent’s plastic bottle contributed the most to our sustainability footprint but opportunities exist to improve bottle resin and recycling.

What is a Life Cycle Analysis (LCA)?

An LCA is an assessment of the environmental footprint of a product where each life cycle or stage of a product’s production, transport and consumption is analysed for its sustainability footprint. See more information on the LCA process at the end of this article.

What did we learn about our ingredients?

Given that protein is the largest input in our formula after water we wanted to make sure we paid particular attention to it when we first formulated the product but also as part of the LCA.

Why plant protein?

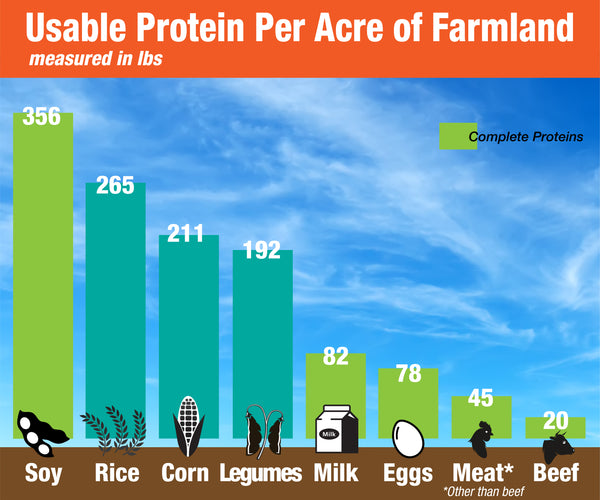

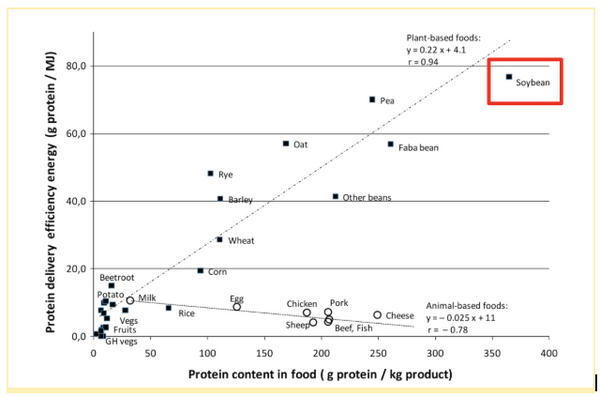

When we first designed our products, we put a stake in the ground that we would use plant proteins since they are more sustainable. Studies after studies have shown that most plant proteins use less resources and are more efficient to produce when compared to animal protein; Most plant proteins sources use less land (figure 1), requires less energy (figure 2), produce less CO2 emissions and typically use less water than animal proteins.1,2,3

|

| Figure 1. Usable protein per acre of farmland measured in lbs. Source: FAO/WHO/Unicef Protein Advisory Board 2004 |

Was choosing soy protein the right choice from a sustainability perspective?

After a few early product iterations made with rice protein, we settled on choosing soy protein isolate as the source of protein in our products. We did so first and foremost for nutritional reasons; soy protein is a complete protein (It is the only plant protein to have a PDCAAS of 1), it has great health benefits (more on that in this blogpost) and it tastes better than other plant proteins. We also chose soy because there was enough soy protein available from US grown soybeans to cover our needs and because soy has a good sustainability track record.1 Soy can improve soil health because it is a nitrogen fixing crop which means that it harbours bacteria that can fix nitrogen from the atmosphere as fertilizer for the plant, greatly reducing the amount of fertilizer that must be used to grow soy compared to other non-legume crops.2 Soy also produces the most usable protein per acre out of all plant and animal proteins in western agricultural system (figure 1).1 It is also the most energy efficient protein to produce (figure 2).1

|

| Figure 2. Protein delivery efficiency in terms of energy use as a function of food protein content. © 2014 American Society for Nutrition |

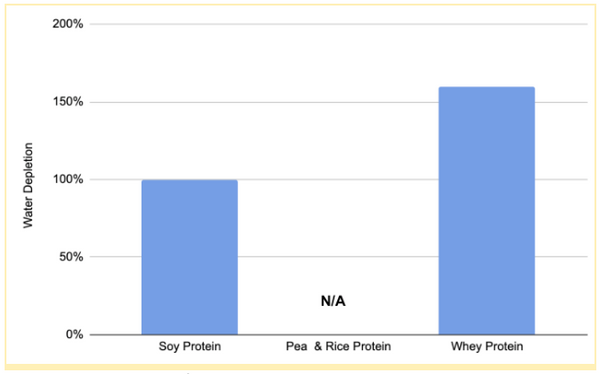

Our LCA results showed us that soy protein isolate had the biggest environmental impact out of all our ingredients but that being said it is also our biggest input. To see if we could find a better source of protein to replace soy, our LCA also included an analysis of the impact of other sources of protein that are commonly available and could replace soy in our formula to deliver 20g of protein per bottle. Whey protein isolate and a blend of pea and rice protein were chosen on that basis (pea protein has a lower protein quality than soy and whey and was blended with rice protein to standardized all products to a PDCAAS of 1). Soy protein isolate was the most sustainable option compared to both whey protein isolate and the blend of pea and rice protein based on these protein’s global warming potential (figure 3). Soy protein isolate also fared better than whey protein isolate as it relates to its impact on water depletion (figure 4).

|

| Figure 3. Global warming potential (Kg CO2 emission equivalent) of Soylent drink made with various sources of protein. |

|

| Figure 4. Water depletion in m3 of Soylent drink made with various sources of protein. |

The water depletion results we obtained from the pea and rice protein blend were complicated by these protein’s complex supply chains and although soy protein appeared to have a lesser impact on water use, we chose to further investigate our results before sharing them.

How does Soylent’s footprint compared to other food options it replaces? Is Soylent solving food voids in a sustainable way?

By conducting an LCA we wanted to understand if we made the right choices when we picked our ingredients but also understand what kind of impact our meal replacement drink has compared with other meals. We decided to compare our meal replacement with typical American meals such as a fast food meal, a cheeseburger to be exact and home cooked meals such as a pancake breakfast and a trout dinner served with rice and avocados. We chose to include nutritional considerations such as fat, protein, carbohydrates, and calories in the comparison since both nutrient density and sustainability are key pillars of our product design and we wanted to be sure that we could recommend our products based on both pillars.

All recipes for the meals were created to deliver 400 calories through approximately 27% fat, 47% carbs and 26% protein to best aligned with our Soylent Drinks.

|

|

|

| - 2 eggs - 2 pancakes with 1 Tbsp of butter - 1 slice of bacon |

- 2 oz broiled beef patty - 1 sesame bun - 1 slice of cheddar cheese - 1 slice of tomato - 1 leaf of iceberg lettuce |

- 2.5oz rainbow trout - 2/3 of a fresh avocado - 4oz of brown rice |

The results: Soylent is more sustainable than all 3 meals on all measures used in the study to assess environmental impact including global warming potential (CO2 emissions) (figure 5.)

|

| Figure 5. Global warming potential (Kg CO2 equivalent) of Soylent meal replacement drink vs. other meals (standardized for calories and macronutrients). |

What about our packaging?

Our HDPE bottle production requires the most energy and fossil fuel out of all the life cycle phases of our product life cycle and also contributes the most to the overall environmental impact of our drinks along with raw material extraction. We have recently transitioned our bottles to HDPE plastic from PET plastic. We need to use opaque bottles to protect the nutritional quality of our product over its year long shelf life and HDPE plastic which is opaque is more efficiently recycled than opaque PET plastic. Despite this recent move towards a more recyclable packaging, our LCA study showed us that further improving our packaging by moving to a post-consumer recycled HDPE resin would have a big impact in reducing the carbon footprint of Soylent drinks.

Our LCA study also analysed various scenarios for the end of life of our products and showed that recycling the bottle instead of landfilling it is very impactful to reduce CO2 emissions and water depletion. Landfilling our bottles represented nearly 400% more CO2 emissions than recycling our bottles and 225% of the water use. Overall, If 100% of the Soylent bottle is landfilled at the disposal phase, the environmental impacts more than double across most impact categories so please recycle!

We also learned from the LCA that our corrugated cardboard boxes contribute the most to the global warming potential (Kg CO2 emissions equivalent) of our product at the end of life stage. This is counterintuitive given that we usually think of cardboard as a more sustainable material compared to plastic but since plastic is a more inert material than cardboard it results in less degradation processes in a landfill, resulting in reduced emission impact for HDPE plastic compared to cardboard. To address this issue, we are currently planning a transition to more sustainable corrugated boxes for the first half of 2020 which should result in a reduction in cardboard use of approximately 1 thousand tonne annually.

What were other opportunities for us?

In our LCA study, we analyzed how different flavors of Soylent drinks compared in terms of sustainability footprint. We found that the Cacao and Café Mocha varieties require more water and contributed more to eutrophication (nutrient runoff into waterways) than our Original Soylent drink. This is due to the coffee and cacao powder we use in these formulas. These ingredients are produced abroad unlike our other ingredients and therefore contribute to emission in transport. Also, cacao and coffee are crops with poor sustainability records. As a next step, we will look to source more sustainable cacao and coffee sources to ensure that we can continue to provide these delicious flavors at a lesser environmental cost while maintaining the affordability of our products and retaining the health benefits of having real cacao and coffee in our products; More on this in 2020.

What’s Next?

While we confirmed that soy is still our best option today to deliver complete protein in our drinks in the most sustainable manner, we are committed to always challenging ourselves and are already making investments in the latest advancement in food technology to offer more sustainable options. New breakthroughs in clean nutrition using cellular technology are within reach and we are committed to leading the way to continue to achieve our mission.

Summary

By completing an LCA on our bottled drink line over the last year, we can confidently say that Soylent meal replacement drinks are “green”. We have validated our choice of offering soy-based products. We also know that we can recommend Soylent as a nutrient dense and sustainable option to solve food voids. But we also know that we still have work to do to improve our sustainability footprint.

Want to learn more about how the LCA process works?

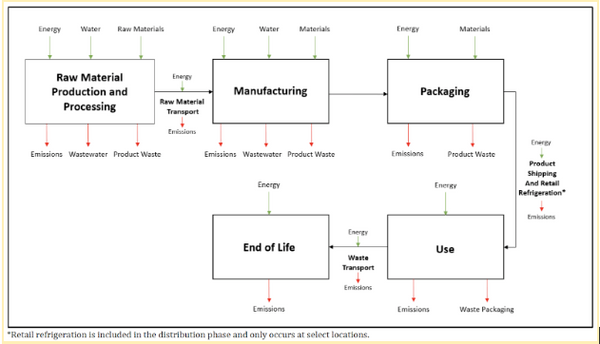

The LCA that we commissioned was very detailed to be as close as possible to the true environmental impact of our product and takes into account literally all aspects of our product’s life cycles such as the irrigation systems necessary to grow crops, the soil transformation needed to grow those same crops, the sources of electricity at the manufacturing plant. The study even takes into account the refrigeration of Soylent products before consumption (they are best enjoyed cold even though they don’t need refrigeration) and refrigeration in the retail location where Soylent is sold in a cold case. At each step, the materials and energy going in and the emissions, wastewater and waste produced were taken into account (figure 6). The researchers who completed our LCA also looked in depth at the fate of our packaging once the product was consumed and measured the impact of recycling versus landfilling.

|

| Figure 6. Product Life Cycle Overview |

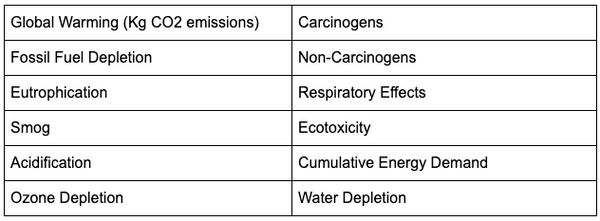

Understanding the sustainability impact of a product is fairly complex and requires taking into account various measures because something that could generate very little emissions may have required lots of water to produce or cause the release of toxic chemicals. Therefore, in our LCA, we followed best practices and used the following measures to understand our footprint across our ingredient selection, packaging, manufacturing, transport and packaging disposal.

Measures used in Life Cycle Analysis for Soylent Drinks

Soylent’s LCA study was conducted by Sustainable Solutions Corporation in 2019 according to the life cycle inventory (LCI) and life cycle impact assessment (LCIA) standards established by the International Organization for Standardization (ISO) life cycle assessment standards ISO 14040 series. The geographic boundary for this study was predominantly North America. The LCA was independently reviewed by a panel made up of experts in the sustainability field: Martin Heller, PhD, Center for Sustainable Systems- University of Michigan; Thomas Gloria, PhD, Director, Industrial Ecology Consultants; Greg Thoma, PhD, Bates Teaching Professor of Chemical Engineering- University of Arkansas.

References

1. Joan Sabaté, Sam Soret. Sustainability of plant-based diets: back to the future, The American Journal of Clinical Nutrition, Volume 100, Issue suppl_1, July 2014, Pages 476S–482S,

2. S.R. Nadathur, J.P.D Wanasundara and L. Scanlin. Proteins in the Diet: Challenges in Feeding the Global Population. Sustainable Protein Sources. Academic Press, Oct 2, 2016

3. Michelle Braun, Ivan Muñoz, Jannick H Schmidt, and Mikkel Thrane. Sustainability of Soy Protein from Life Cycle Assessment. The FASEB Journal 2016 30:1_supplement, 894.5-894.5

_______________________________________

Julie Daoust, PhD, Soylent VP Product Development & Innovation.