This week, #SoylentForGood is proudly renewing our support for World Food Program USA for the third year in a row. Without you, our loyal customers, we wouldn’t be able to fund such programs, so we also wanted to take this opportunity to say THANK YOU.

Recap of Soylent and WFP USA:

Beginning in May 2016, Soylent became an official supporter of World Food Program USA, a non-profit organization that supports the lifesaving work of the United Nations World Food Programme (WFP), the global leader in the fight to end hunger.

Recently, we have directed most of our funding to the WFP’s Innovation Accelerator. Launched in 2016, WFP’s Innovation Accelerator identifies, supports and scales up solutions to address global hunger. They address global malnutrition while developing technologies that can prevent food scarcity for the long term. Challenging the status quo is in our DNA at Soylent, so this new initiative at WFP quickly caught our team’s attention. While we believe that Soylent can help in many situations and circumstances, we also recognize that we do not have all the answers. Just as our founder Rob Rhinehart’s entrepreneurial spirit sought to solve some of the issues with our global food ecosystem and consequently created Soylent, we want to help support new, promising ideas that help further our vision.

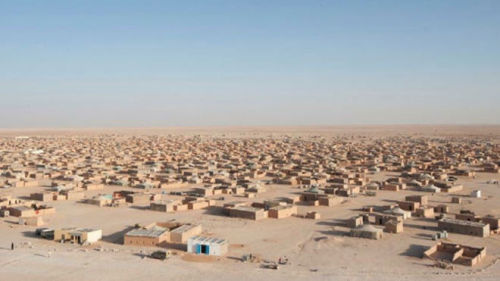

For 42 years, Sahrawi refugees have been living amongst five camps in the Sahara desert near the town of Tindouf in Western Algeria. WFP supports 125,000 of the most vulnerable. The harsh and isolated desert environment has limited opportunities for agriculture and self-reliance. Though helped by humanitarian assistance, food security assessments have shown that 19% of Sahrawi children under 5 suffer from chronic malnutrition and 43% of Sahrawi women between the ages of 15 and 49 suffer from anemia within the camps.

Soylent helps bring sustainable Feed Production with Hydrograss in the Sahara

WFP’s Innovation Accelerator and Soylent are bringing new technology to camps in the Sahara to help refugees produce their own food: Hydroponics

With low-tech hydroponic systems and a blend of nutrients targeted at the exposed roots, plants are able to quickly grow and thrive in the desert without soil or a lot of water.

During the first phase of this pilot (November 2016 – April 2017), WFP and OXFAM tested the concept of growing barley in the desert with a high-tech container unit and adapted the technology to local needs with the support of Sahrawi engineer Taleb and other refugees. As a result, with the support of Soylent, the refugee community developed the new Hydroponic Fodder unit and adapted it to local conditions. The unit can now be produced at 10% of the cost of the previous version by using only locally available materials, which contributes to the sustainability and ownership of the initiative.

The first use case for these units has been to grow barley grass, which is among the fastest-growing, high-nutrition feed sources for livestock, thus providing key sustenance and nutrients for the chain of life in the Sahara. Growth takes 7 days from seed to harvest, with 10% of the water requirements and none of the soil requirements of traditional methods.

Prior to the hydro grass units, livestock relied on garbage as a source of nutrition, leading to poor health and consequently little value to the refugees. The results of the project have been very promising, more than doubling milk production and increasing the health, life expectancy, and reproduction of the local goats. Now, families can provide more milk to their kids. This innovative approach shows tremendous promise of improving the nutritional status of the families and improving the camp’s resilience and self-reliance.

Soylent believes in the promise of plant-based diets. However, we also want to ensure that all people receive a complete meal, for example in areas like the desert, where a nutritious plant-based-only meal may not be accessible. While the earliest applications have been for animal feed, we are excited at the prospect that the same concept and technology will also be used to grow fresh produce to be directly consumed by people. Currently, the first tests for fresh hydroponic vegetable production in the camps are being conducted. This pilot in Algeria was so successful, it is now being replicated in countries like Sudan (again with Soylent’s support) as well as Chad with increasing applications beyond the animal feed. In Peru, a localized Hydroponic DIY solution was developed with families living in slums to grow vegetables for their own consumption.

Your purchase of Soylent supports the development of sustainable technologies we believe are the most promising for ending food insecurity and improving the quality of nutrition around the world.

If you want to help us in our efforts, help spread the word. For every Friend Referral, we donate $1 to WFP USA!

Why Hydrograss Can Work:

- Hydroponic grass modules are owned by entrepreneurial Sahrawi refugees and their families. Growing hydroponic grass and hydro grains allow these vulnerable people to produce their own food and rely less on international aid.

- Hydroponic barley grass, as a primary hydroponic grass, provides highly nutritious food for livestock and humans.

- Hydroponic cultivation uses 90% less water than conventional agriculture. Hydroponic grasses like barley require a minimum amount of water, materials, inputs, and labor. Hydroponic grass modular units are simply designed with locally available materials.

- The local adaptation of the units, supported by Soylent has helped to reduce the cost of each unit to 10%

- Because Hydroponic barley grass cultivation does not require soil and does not grow very tall, it can be vertically farmed, saving space and energy. This makes growing fresh food possible in an area, where no traditional cultivation was possible before.

- Hydroponic systems can be adapted to grow various feed and vegetable crops, which is the next step.

- Training and ongoing support, along with accessibility, storage, and logistics, are a key part of the program.